You might be heard about Carbon Fiber, or you are already using it, in today’s world, it’s no longer a very expensive material, from industry to our life, we can see the carbon fiber products everywhere. Because of its superior properties, carbon fiber is being utilized in an ever-expanding range of applications. Today, Sinofibre invites you to explore the fascinating world of carbon fiber.

What is Carbon Fiber?

Carbon fibers are produced from precursors such as polyacrylonitrile (PAN) and rayon. These precursor fibers undergo chemical treatment, heating, and stretching, followed by carbonization to create high-strength fibers. With a carbon content exceeding 90%, carbon fiber boasts exceptional performance advantages, including high temperature resistance, high strength, and corrosion resistance.

Production Process for Carbon Fiber

The production of carbon fiber typically involves several key steps:

Spinning: Converting precursor materials (like polyacrylonitrile – PAN) into fibers.

Stabilization: Heating the fibers to stabilize the molecular structure.

Carbonization: Subjecting the stabilized fibers to high temperatures (above 1000°C) in an inert atmosphere to remove non-carbon elements.

Surface Treatment: Enhancing the bonding properties of the fibers.

Sizing: Applying a protective coating to the fibers to improve handling and processing.

Weaving: Weaving the carbon fibers into various patterns (e.g., plain weave, twill weave, satin weave or Unidirectional weave) to create carbon fiber fabric. This step is very important for applications requiring specific directional strength properties.

Prepreg: Impregnating the woven carbon fiber fabric with resin to produce prepreg materials. Prepregs are ready-to-use composite materials that ensure uniform resin distribution and optimal fiber wet-out.

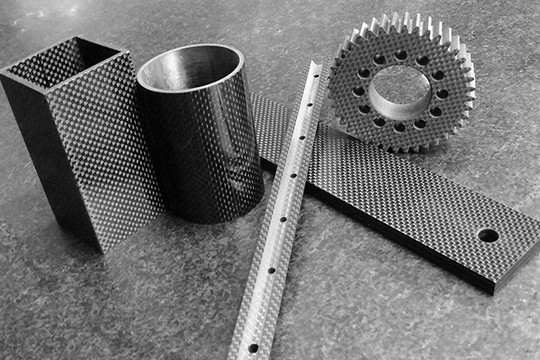

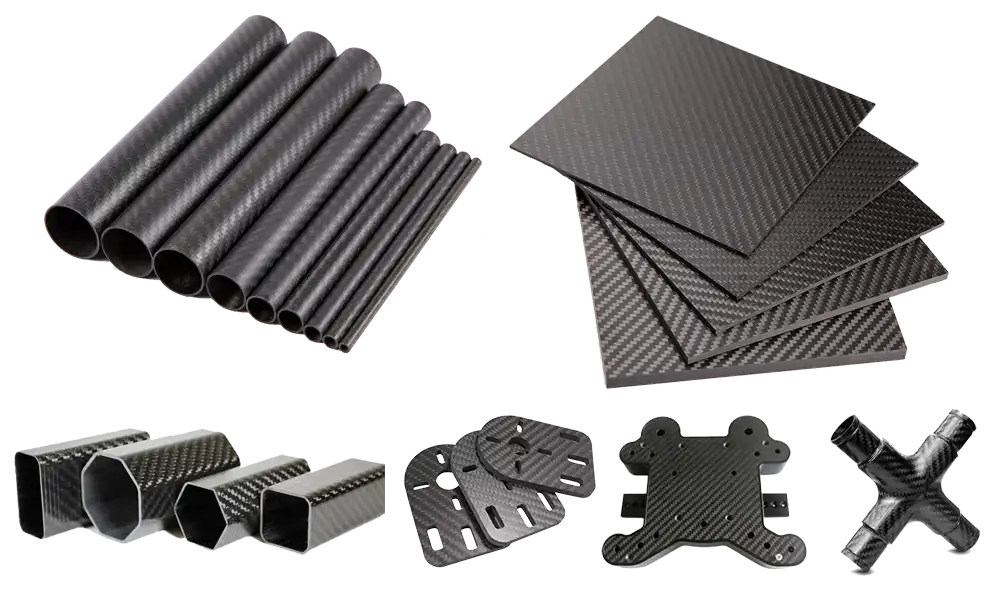

Shapes of Carbon Fiber Products

Because of its good flexible property, carbon fiber can be shaped into various forms using different techniques, typically including:

Carbon Fiber Sheets: Compression or Autoclave technique

Carbon Fiber Tubes: Roll molding technique

Carbon Fiber Rods: Pultrusion technique

Carbon Fiber Parts: Cutting from CNC router or Compression technique

For detailed information on these techniques, click the corresponding link above.

Properties

Carbon fiber products have many characteristics, people like it because its main properties:

High strength: Carbon fiber is five times stronger than steel and twice as stiff, yet it is significantly lighter. This makes it ideal for applications where reducing weight with high strength

Lightweight: The density of Sinofibre’s carbon fiber products is 1.6 -1.8 g/cm³, it’s much lighter than metals like aluminum (2.7 g/cm³), copper (8.9 g/cm³), and steel (7.8 g/cm³). its weight reduction means to fuel savings and improved performance.

Super High Tensile Strength: Carbon fiber exhibits tensile strengths typically in the range of 3,500 to 6,000 MPa (Base on the grade from T300 – T800), it’s much higher than aluminum (400-550 MPa), copper (210 MPa), and steel (500-1,200 MPa).

High Stiffness: The modulus of elasticity of carbon fiber is around 240 GPa, which is higher than that of aluminum (69 GPa), copper (110-128 GPa), and comparable to steel (200 GPa), making it exceptionally rigid and resistant to deformation.

Thermal Resistance: Carbon fiber can withstand temperatures above 1,000°C without losing its strength, unlike metals that may weaken or melt at high temperatures.

Chemical Resistance: It is resistant to corrosion and chemical attack, unlike metals that may corrode when exposed to moisture and chemicals.

Fatigue Resistance: Carbon fiber exhibits excellent fatigue resistance, maintaining its mechanical properties under cyclic loading conditions better than many metals.

Low Thermal Expansion: It has a very low coefficient of thermal expansion, meaning it does not expand or contract significantly with temperature changes, ensuring dimensional stability.

丨Comparison with Other Materials

| Property | Carbon Fiber | Steel | Aluminum | Copper | Titanium |

|---|---|---|---|---|---|

| Density (g/cm³) | 1.6 | 7.8 | 2.7 | 8.9 | 4.5 |

| Tensile Strength (MPa) | 3,500 – 6,000 | 500 – 1,200 | 400 – 550 | 210 | 900 – 1,200 |

| Modulus of Elasticity (GPa) | 240 | 200 | 69 | 110-128 | 110 |

| Thermal Conductivity (W/mK) | 5-10 | 50 | 235 | 400 | 22 |

| Corrosion Resistance | Excellent | Poor | Good | Poor | Excellent |

| Fatigue Resistance | Excellent | Good | Good | Fair | Excellent |

Applications of Carbon Fiber Products

As we mentioned at the beginning, the price of carbon fiber is much lower than before, so it has been used in more and more applications:

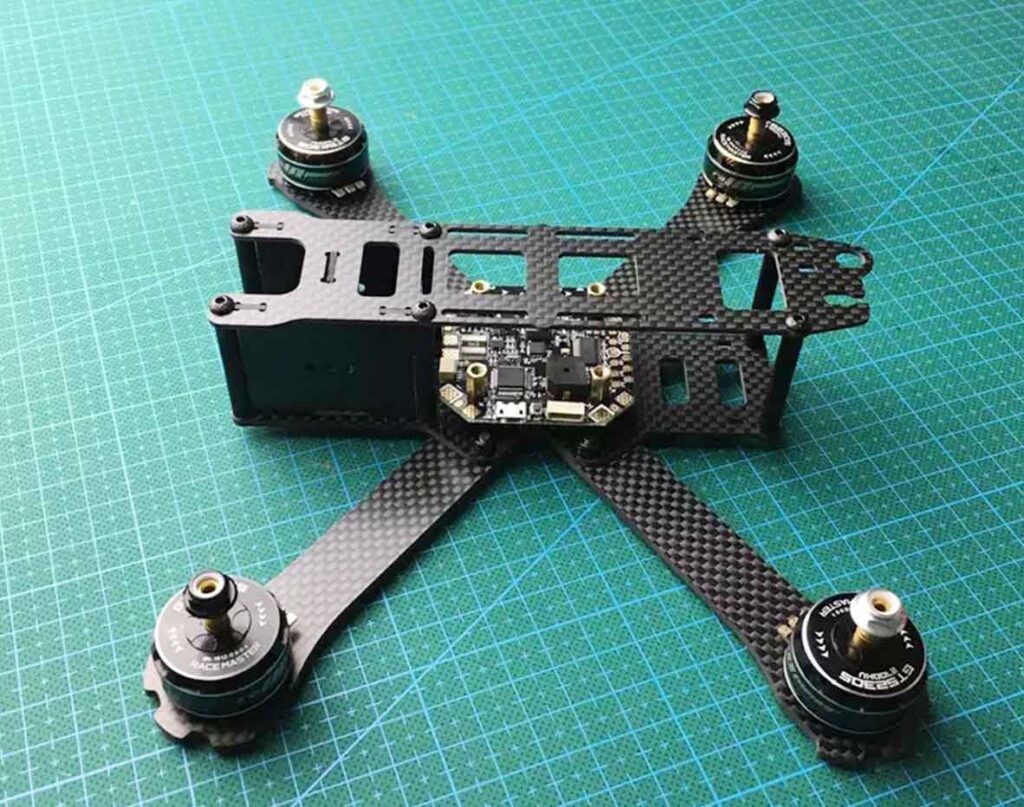

UAV / Drone

Most of the UAV or Drone are made of carbon fiber plate and tube because it has lightweight, high-strength properties, enhancing flight performance and efficiency, to get a higher battery life.

Sporting Goods

Due to the lightweight and durable can enhance tools performance, more and more tools are made of carbon fiber, such as Bicycles, Tennis rackets, Golf clubs, Fishing rod and Paddle etc.

Automobile

It’s also because of its light weight and high strength, contributing to better fuel efficiency and performance.

Aerospace Industry

In aerospace, carbon fiber is crucial for reducing the weight of aircraft and spacecraft, leading to improved fuel efficiency and performance. Components like fuselages, wings, and satellite structures benefit from its lightweight and high-strength properties. However, the grade is much higher than the standard carbon fiber. If you want know more grade about the grade of carbon fiber, please refer my post <What is T300, T700 and T800 Carbon Fiber>

Medical Field

In the medical field, carbon fiber is used in prosthetics, orthotic devices, and medical imaging equipment due to its strength, light weight, and radiolucency (transparency to X-rays).

Wind Energy

Wind turbine blades made of carbon fiber are more efficient and durable than the traditional one like Fiberglass, leading to better energy capture and reduced maintenance costs.

Future of Carbon Fiber

With technological breakthroughs reduce the manufacturing and raw material costs, carbon fiber is becoming more accessible and affordable. More and more material will be change to high strength carbon fiber products, which will expand its applications and accessibility.

Conclusion

Carbon fiber is a remarkable and new material with unique properties and a wide range of applications. It became more and more popular mainly due to its lightweight, Flexible, Superior high tensile strength, which can save energy and enhance properties. As technology advances, carbon fiber will undoubtedly to be a wide range material in the future.

One Response

I am not suhre wherre you’re getting your information, buut great topic.

I needs to spend ssome time learning much more or understanding more.

Thanks for great info I was looking for this information for mmy mission. https://Bandur-art.blogspot.com/2024/08/the-ultimate-guide-to-no-mans-sky-mods.html